Finishing

- Electrophoretic Coating

- Powder Coating

- Wet Painting

- Phosphating (Zn & Fe)

- Galvanizing

- Galvanizing

The Electrophoretic (e-coat) painting process is universally used on all modern vehicle shells, bracketry and panels.

Who uses E-Coat?

The E-Coat Process (or KTL) is used by every major automotive manufacturer in the world. Over 95% of the world's motor vehicles are primer-protected with the cathodic electrocoat process.

Why do they use E-Coat?

There is no better way to add front-line corrosion protection coating to a complex assembly like a vehicle bodyshell. Over 300 million vehicles have been coated with this process to date!

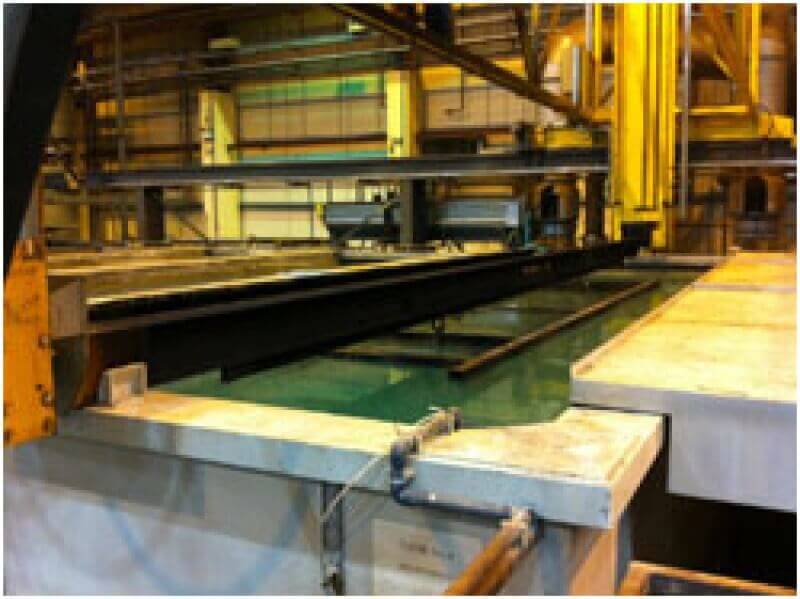

How is E-Coat applied?

Shells and components are immersed in an 11-stage cleaning and pre-treatment process that deposits a corrosion-resistant layer of Zn/Mn/Ni Phosphate. They are then immersed into the PPG Electrophoretic Epoxy Primer which is electrically bonded to the surface before being cured in an oven at 185ºC for 45 minutes leaving an impermeable, durable primer finish.

The E-coat is very penetrating and far more effective than spray-applied primers. However, as with any process, we cannot guarantee 100% coverage.

When painting your project don't take risks.

Unlike many other products, PPG E-coat is fully compatible with all brands of automotive-approved refinishing paint systems.